Demystifying Mechanical Ventilation: The Different Types and How They Can Benefit You

- Jennifer Crowley

- Jul 31, 2023

- 2 min read

Updated: Jul 9, 2024

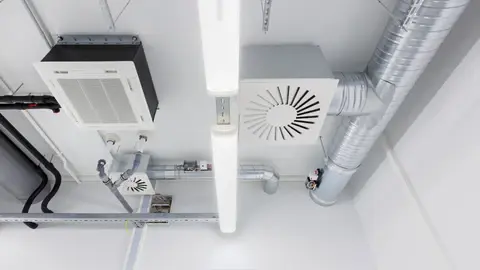

Mechanical ventilation is an essential aspect of building design, particularly in modern construction, where structures are designed to be airtight for energy efficiency reasons. Ventilation systems help to improve indoor air quality by controlling the flow of air and moisture in and out of a building, which can have a significant impact on the health and well-being of the occupants.

There are several types of mechanical ventilation systems that are commonly used in buildings. In this blog post, we will explore the four main types of mechanical ventilation: supply ventilation, exhaust ventilation, balanced ventilation, and whole-house mechanical ventilation.

1. Supply Ventilation

Supply ventilation is a type of mechanical ventilation system that introduces fresh air into a building through a supply duct. The air is typically filtered to remove pollutants and other contaminants before it is circulated into the building. Supply ventilation systems work by pressurizing the building, which forces stale air out through small cracks and leaks in the building envelope. This can be done using a centralized system, with air being brought in through a single duct and distributed through a series of vents, or through a decentralized system, where individual units are installed in each room or area. This type of system is ideal for buildings located in areas with high levels of outdoor pollution, as it helps to maintain a steady flow of fresh, clean air.

2. Exhaust Ventilation

Exhaust ventilation is a type of mechanical ventilation system that removes stale air from a building through an exhaust duct. The system works by creating negative pressure in the building, which draws in fresh air from outside through small cracks and leaks in the building envelope. Exhaust ventilation systems are typically used in buildings with high levels of indoor pollutants, such as kitchens and bathrooms. They are also commonly used in conjunction with supply ventilation systems to maintain a balance between the intake and exhaust of air in the building. This can be done using a centralized or decentralized system and is often used in conjunction with supply ventilation to ensure a continuous supply of fresh air.

3. Balanced Ventilation

Balanced ventilation is a type of mechanical ventilation system that introduces fresh air into a building through a supply duct and removes stale air through an exhaust duct. The system works by maintaining a balance between the intake and exhaust of air, which helps to maintain a steady flow of fresh air into the building. Balanced ventilation systems are ideal for buildings with a moderate level of outdoor pollutants and a relatively constant temperature and humidity level.

4. Whole-house Mechanical Ventilation

This system is used to change the air in the entire house; it is often used with a central air-conditioning and heating system, which can be either a centralized or decentralized system.

Each type of mechanical ventilation system has its own advantages and disadvantages. The best system for a particular application will depend on factors such as the size and layout of the building, the number of occupants, and the specific ventilation needs of the space.